Selection of yarn for any one particular application depends on many parameters. The thickness (density) of the thread is the main parameter, which determines that the quality of the finished product functional and aesthetic requirements. The thickness (density) of the thread is determined by the number, which is the ratio of its length and weight given yarn numbering systems, and is written as a number. To determine the thickness of the filaments is necessary to know the different strands of the numbering system and their relationships.

Yarn numbering systems of constant mass and constant length

All yarns thickness detection system is divided into two types - numbering system filaments constant weight and constant yarn length numbering system.

- The system of numbering yarns constant weight yarn weight is constant, and the yarn length is calculated according to the formula. With the growing number of threads the thread thickness is reduced.

- The system of numbering the threads of constant length length of the string is constant, and the filament mass is calculated by the formula. With the growing number of threads increases the thickness of the thread / yarn becomes coarser.

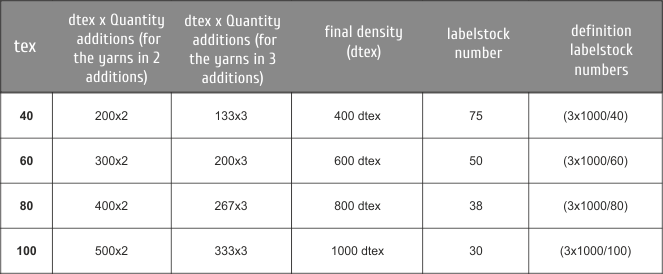

Metric numbering system used to denote the thickness of synthetic staple yarns and reinforced, and the English numbering system - to indicate the thickness of cotton yarn. The density of the filaments is typically expressed in denier or decitex. When the thread is made up of several intertwined additions, you must calculate the total value of the filament size, taking into account the density of all additions. The numbering system of constant mass of strands: the total value of the filament size = density of each addition / number of numbering systems slozheniy.V threads of constant length: the size of the total value of the density of each yarn = addition of x number of additions. The final value of the filament size can be accessed by any number of additions.

Translation units measures yarn thickness

Label numbering

Label numbering - commercial yarn numbering system. Label number - is not nothing but a label marking thread density in the system adopted by the specific manufacturer of yarns. The metric numbering system, the system measures the cotton denier and density determination system uses the numbering system of label strands to determine the approximate thickness of the finished strand of a particular size. The density indicated on the label number of threads of one type does not coincide with a density indicated on the label room yarns of another type. For example, the thickness of the cotton yarn of 40 numbers will be noticeably different from the thickness of the reinforced filaments in the same issue. The principle of determining the thickness of the threads on the label numbering system is similar to the principle of determining the thickness of the threads on the numbering system of constant mass of filaments.

Value numbers and thread thickness:

- The more labelstock number, the finer the thread.

- The labelstock smaller the number, the thicker yarn.

Translation yarn sizes in the labelstock number

To translate any number tex in the labelstock number, you need to divide the number of 1000 tex and multiply the quotient by 3. Today, cotton yarn rarely used, so there is not provided information on the label non-cotton yarns.

Determining the thickness of the thread on the label number

Manufacturers of yarns in different countries have different label numbering principles. Knowing the different numbering systems strands certain density and size of the respective tex will help you in choosing the right yarn density. In the tables below, the label numbers are three different types of filaments, the density of which is specified in units of different filament numbering systems.The various thread numbering system - reinforced multifilament yarns of polyester / cotton

The various label numbering system - reinforced polyester thread

The various label numbering system - polyester staple yarn

Русский

Русский  Українська

Українська  English

English

Posted by

Posted by

Note: HTML is not translated!